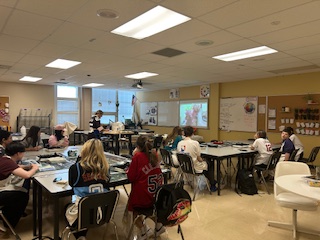

With the ribbon cutting on Sept. 9, 2025, two long-awaited courses — welding and micro-electro-mechanical systems (MEMS) — have been formally introduced into the West Shore curriculum at Lakewood High School. Students finally have the opportunity to gain practical in-field experience in the two career fields that are becoming increasingly critical to the U.S. job market.

These two new programs are a result of a $5.78 million grant awarded in fall 2023 to expand the career-tech program at Lakewood High School, which also serves Bay Village, Rocky River, and Westlake. “The state of Ohio put this grant out there for career-tech districts, $200 million, and basically said: Hey, if you want to expand career education, here’s a grant,” said Dr. Yakoob Badat, the West Shore Career-Tech Coordinator. This expansion of the career-tech program is a response to the growing demand for skilled workers needed for the maintenance of the aging U.S. infrastructure and the manufacturing of silicon chips, which has become increasingly vital to modern society.

Despite the need for other skilled labor fields such as electrical work and plumbing, welding and MEMS were better aligned with the U.S. job market. “But, you know, we lean to workforce development partners like Team Neo to look at the job market reports and look at what’s out there in industry, and make a decision based on what’s going to be needed — and that’s why we decided on those two programs,” Badat said.

Before Badat became the West Shore Career-Technical Education Coordinator in fall 2023, Bill DiMascio held the position. Regarding the grant, DiMascio did “the majority of the work. The superintendent helped, the assistant superintendent, Dr. Palumbo, helped, and a couple of other folks helped,” Badat said. Regarding the grant, the State of Ohio—according to its website—offered career-tech districts in 2023 funding for any program the grant recipients chose, as long as it held relevance to the job market or innovation.

A Deeper Look: Welding

“It was decided that welding is a pretty good program for students to participate in,” said Badat. Welding as a career field has seen a shortage of workers since the 2000s, due to the decreased interest in the field for a variety of reasons, such as the tiresome work and the large aging workforce beginning to retire. This shortage of workers only exacerbates the issue of the aging American infrastructure.

“I believe right now the nation needs like 80,000 plus workers, but not a lot of people are really interested in welding anymore,” said Lakewood High School senior Rian Fetting.

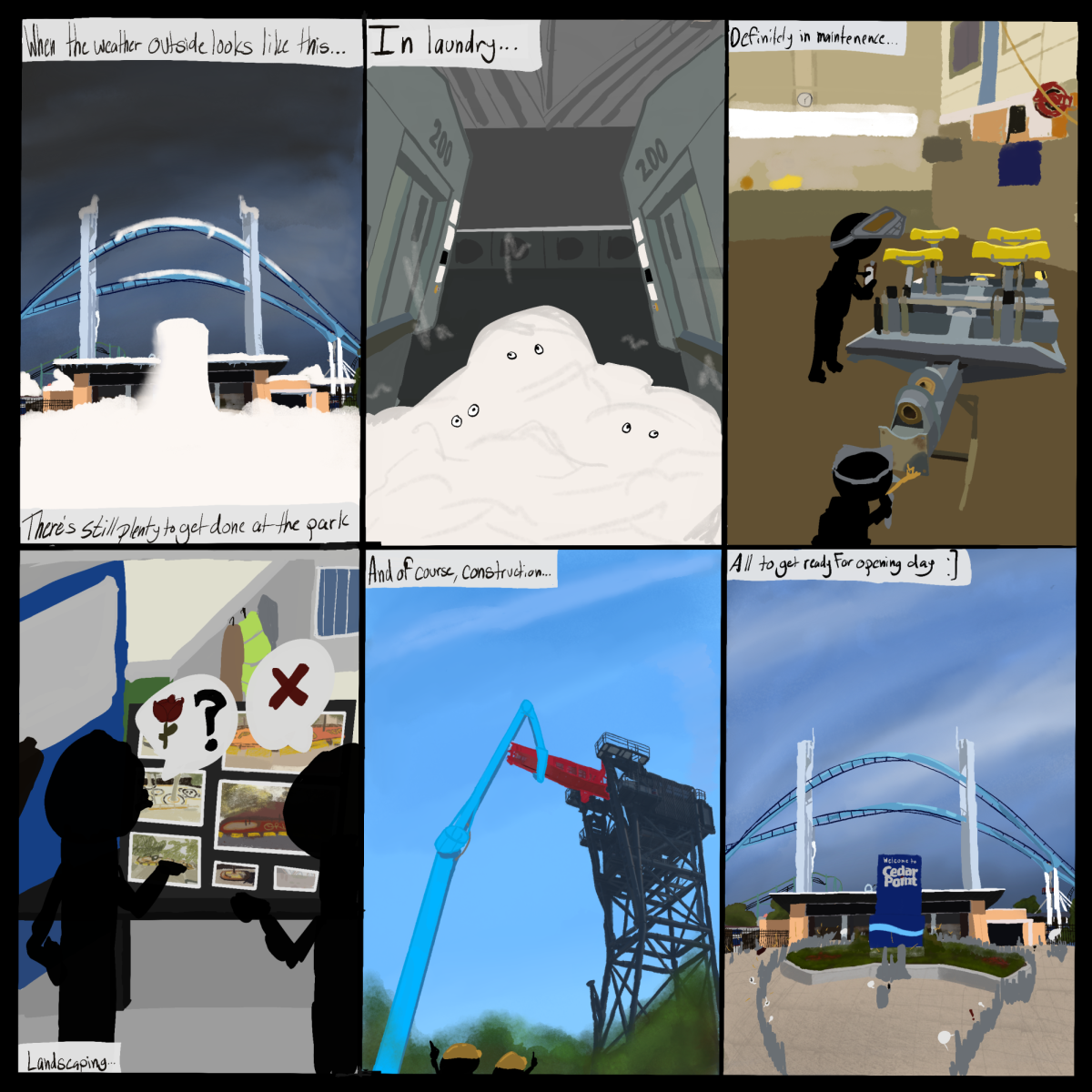

Students of the welding course can expect the program to be broken down to the basics and skills, such as safety and welding principles, before progressing into learning the four main processes of the trade: Stick, TIG, MIG, and Flux Core. They also learn plasma arc cutting, oxy-fuel cutting, and carbon arc gouging. Each skill learned comes with a set of credentials. “So when I sprinkle in cutting on top of the welding process, they can earn a whole bunch of different credentials,” said welding instructor Joseph Zrnich. “So that’s where that 50 credentials [come from]”.

Due to welding just being introduced in the West Shore curriculum, seniors taking this class will take only the first part of the two-year course. “Despite the shortened course, when they have their through, they will succeed, as long as they can apply those basics of concepts,” said Zrnich. “So the iron workers will hire them, even if it’s one year.” These credentials, received upon graduation, qualify students to enter the workforce—even if it is just the bare minimum 12 credits required to graduate from the American Welding Society curriculum—or to continue into post-secondary.

Rian Fetting, a senior at the high school, aspires to enter the welding field as an ironworker. “The first project I hope to be on as an actual ironworker is the new Browns stadium — hopefully this summer or next summer,” he said. He also noted that the benefits are excellent, with the industry standard being retirement after 25 years of work, along with a pension and savings account. “If you go the union route with someone like a pipe fitter and ironworker, you can be making around $100,000 right off the bat. But if you go to a weld shop, you can be making $40,000 to $80,000 right away — but after a few years, you’ll most likely make six figures,” Fetting said.

However, this class isn’t limited to only those who desire to enter the workforce as lifelong welders; it is also available for those who desire to learn welding as a skill. “I see myself in a different career, but I will be very happy to have welding as one of my main skills,” said Aeld Allkushi, a senior at Lakewood High School.

A Deeper Look: MEMS

The addition of MEMS to the West Shore Career-Tech curriculum has had a different story. “The origin story of this is very much a bigger-picture idea that stems from the CHIPS Act under Joe Biden, where his main focus was to start some advanced manufacturing in the states, and through some grant funding, West Shore was selected as the only school in Ohio to receive these funds directed at building a workforce,” said MEMS instructor Kyle White.

With ongoing tensions between Taiwan and mainland China, domestic semiconductor manufacturing only becomes a bigger concern by the day, and so does the development of MEMS courses.

Rather than working on the macro scale, students in the MEMS program focus on the microscopic electromechanical systems found in smartphones and cars. In this course, soldering skills, clean-room etiquette, and semiconductor manufacturing are taught.

Along with these skills learned, students receive credentials that apply to the industry and are widely accepted. “We have 22 credentials available for MEMS…the main one is the J Standard 001—that’s specific to soldering. And then they can get the Lean Six Sigma Green Belt certification, Microsoft Office, and SMS,” said Badat.

The factor that sets the MEMS program of West Shore apart from all the other programs is that Lakewood is the only high school in Ohio to have a complete mock clean room, similar to those used in semiconductor manufacturing plants at TSMC or Intel, just on a smaller scale. “We’re the only ones that I know of that have something like that,” said Badat.

The credentials and the skills learned in the mock clean room allow students to enter the workforce as maintenance workers for anything related to circuit boards or to continue into post-secondary education, similar to welding. Students such as Nico Elliot, a junior at the high school, can further their credentials at colleges like Lorain Community College, which is at the forefront of the MEMS career field.

“A starting salary at somewhere like Intel would be somewhere around the range of like $70,000 to $80,000,” said Elliot. West Shore also has an articulation agreement with Lorain Community College, where credentials earned in the MEMS program can be transferred over, enabling students to pursue a bachelor’s or master’s degree.

The Bigger Picture

“Bigger picture, I think, this course—the Welding course—everything West Shore is trying to do and kind of push into the future, as far as workforce goes, is trying to meet the need,” said White.

As these courses meet their full potential, they will shape not only the careers of their graduates but also the future of American infrastructure and semiconductors. “I think we are a proof of [the] concept right now,” said White. “Once we’ve proved this can work and it’s meaningful for students, I think we’ll see a lot of learning”.

Lakewood High School junior, Domenico Sgambellone, expressed his excitement about being part of an exciting new beginning: “You can tell that this is the start of something amazing. I feel lucky to not only be in the place where it’s happening but also to be a junior during the inaugural year of the MEMS program.”